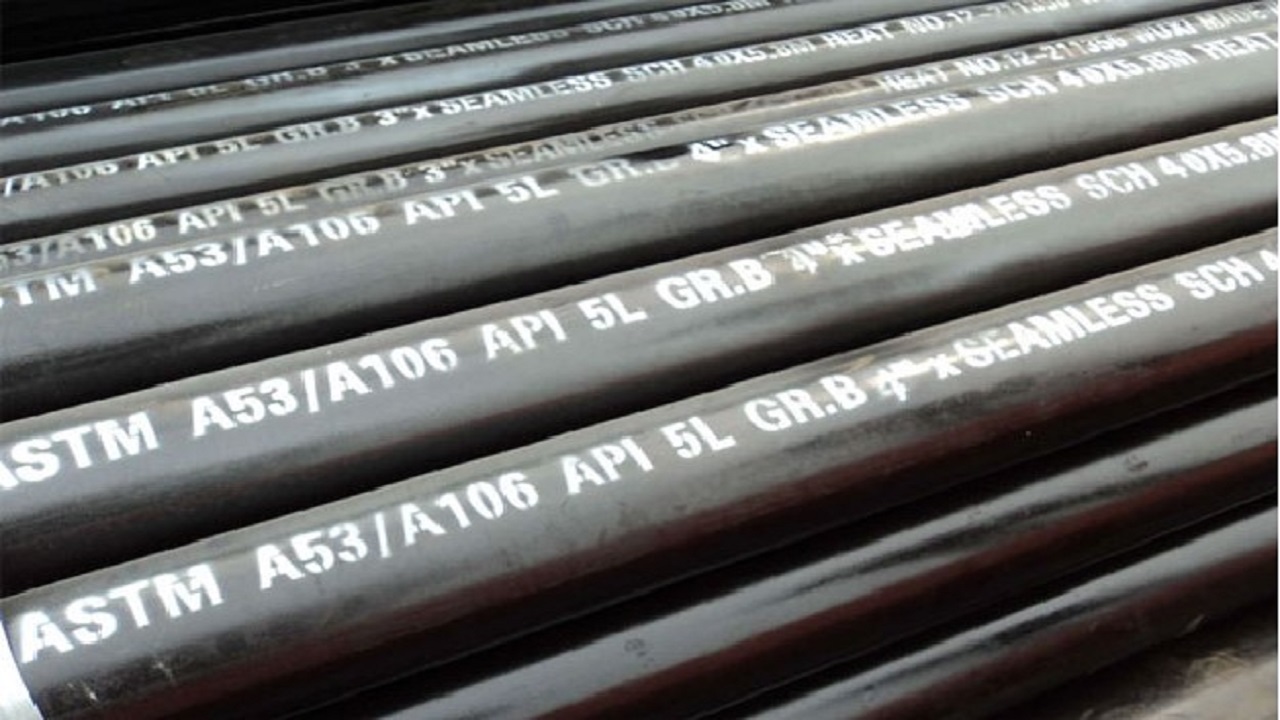

People in the construction business of any pipeline require the use of various materials that range from steel, concrete, and plastic among others that act as key determinants to the lifespan, safety, and overall efficiency of the constructed pipeline. The API has provided a range of grades of steel pipes for pipeline use, out of which API 5L is the most popular. In this article, you will learn API 5L Pipe Grands-GRADE A,B differences, and how to choose the right pipe for your project.

Understanding API 5L Grades

API 5L is an additional line of pipes that are used in the transportation of oil, gas, and water. It includes different grades, mainly Grade A and Grade B while higher grades are X42, X52, and the like. The grades are defined by yield strength, tensile strength, and chemical content which affects the behavior of the pipe in various conditions.

API 5L Grade A

API 5L Grade A is the first grade in the API 5L standard and it is the simplest grade. A characteristic of this grade is it retains a lower yield of strength making it around 24,000 psi compared to Grade B. This grade is normally applied where the strength and performance demands are low or insignificant.

Advantages of Grade A

Cost-Effectiveness

In every form, Grade A pipes are relatively cheaper as compared to the other grades hence they are suitable when cases of cash issues arise in the project. This is the solution for projects that cannot afford high investments.

Flexibility

Their lower strength also makes them more cooperative to bending and twisting and may be prized for this in construction applications. Flexibility is preferred by people in this business.

Lower Weight

As stated before, Grade A pipes are lighter which makes their transportation and installation cheaper. With this, a person can get the most out of their purchase.

Disadvantages of Grade A

Limited Applications

Grade A is slightly weaker than Grade B and therefore not recommended for high-pressure or high-usage applications.

Susceptibility to Corrosion

Although the further increase in corrosion resistance is vested in coatings, the higher carbon may not be capable of withstanding the more severe environment than Grade B.

API 5L Grade B

API 5L Grade B is slightly stronger than API 5L Grade A with a yield strength of about 35,000 psi. This places it also among the most preferred pipelines for various uses that need high endurance and pressure levels.

Advantages of Grade B

Higher Strength

The improved yield strength enables the transport of fluids at elevated pressures while maintaining safety and is ideal for use in oil and natural gas applications. These kinds of pipes are used for hazardous materials so that the chance of accidents can be reduced to zero.

Versatile Applications

Grade B is more suitable for a wide range of applications under various conditions and high stresses.

Better Resistance to Fatigue

It is mechanically more robust than its rival and hence more resistant to fatigue and failure under stress.

Disadvantages of Grade B

Higher Cost

The enhanced strength and performance are achieved at a cost, which may not be affordable for all projects.

Weight Considerations

Grade B is denser than Grade A which may have some effect on transportation and installation cost.

Things to Consider When Deciding between Grade A and Grade B

Project Requirements

What are its specific requirements? In case you are working in a high-pressure pipeline or a corrosive atmosphere, you may need Grade B.

Budget Constraint

However, if the project can afford flexibility in budget, then the use of Grade B may be more economical in the long run because of its quality.

Environmental Conditions

Think about what kind of environment the pipe will be exposed to, temperature and pressure, or the presence of corrosive substances. Grade B is usually better for harsh environments.

Longevity and Maintenance

Assess the frequency with which the pipeline will need to be serviced. The pipes at a higher grade may prove costly at first but will likely gain less maintenance costs in the long run.

Regulatory Standards

Make sure that your decision follows the set laws regarding pipeline construction as well as the acceptable material to be used.

Conclusion

The decision of which pipe to use, API 5L Grade A or Grade B, depends on the project’s needs. While Grade A is useful where applications are not stringent and costs are high, Grade B is more suitable for applications where higher strength and improved durability are required. When evaluating the needs of the project, cost, climate, and other guidelines, you can make the right decision that will help your pipeline project to be successful in the future. Choosing a grade of A or B depends totally on the demands of a project.